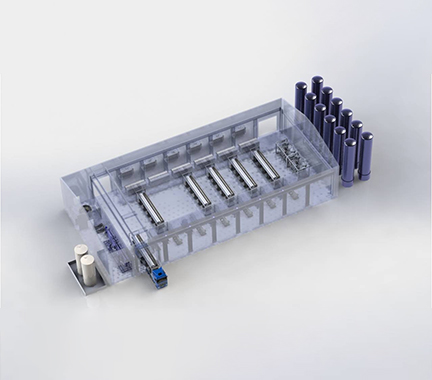

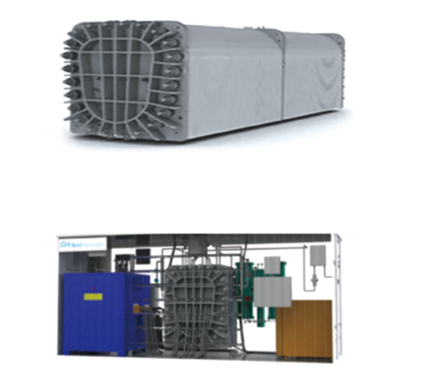

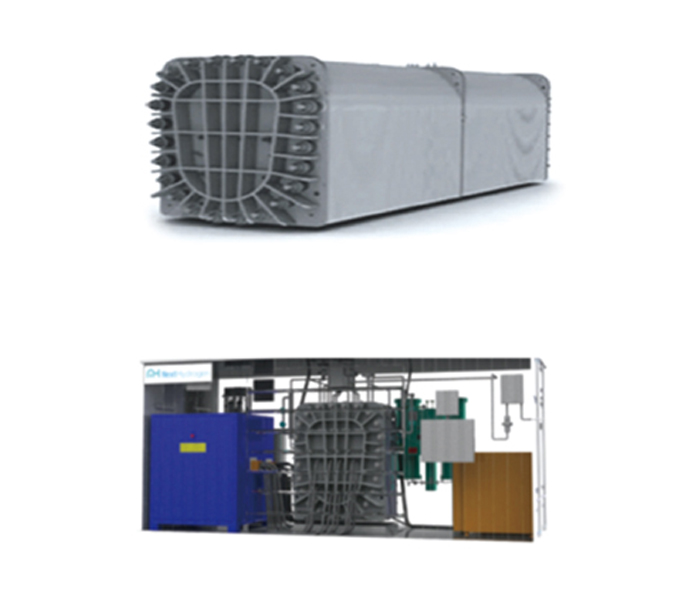

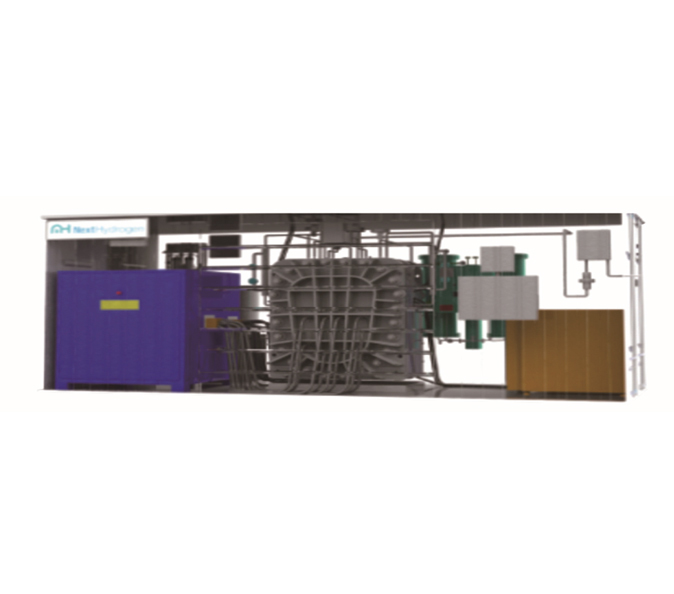

The electrolyzer includes module, skids (processing, drying and purification), cooling water system, PLC control cabinet, rectifier, gas analyzing instruments.

Wide Frequency Alkaline Water Electrolysis Hydrogen Generator

Advantages:

The new generation of wide frequency alkaline water electrolysis hydrogen production equipment can be directly applied to the equipment of wide frequency intermittent power supply, specially designed and developed for intermittent power supply of abandoned wind, abandoned light and abandoned water. Reduce the intermediate power re-transmission to power grid under the P2G mode, reduce unit energy consumption, and greatly improve the project's economic efficiency. The original "overload" electrolyzer operation mode design makes the hydrogen production double in a short time. Therefore, the equipment is more integrated, easy to move and occupy less land and save investment in civil engineering.

Parameter

| Hydrogen Production | Capacity | 75~450Nm3/h |

| Pressure | 6~10barg | |

| Standard Purity | >99% | |

| water content | Saturated gas | |

| After purification | 99.999% | |

| Dew point after treatment | -65″C | |

| Oxygen production | Capacity | 50% hydrogen flow |

| Slow variability rate | Maximum capacity % | 5%/s |

| Power Supply | Voltage | Change along with output |

| Frequency | 50or60hz | |

| Service rating | 3,650kVA |

| system energy consumption | Hydorgen output 225Nn3/h | With drying system | 5.9kWh/Nm3 |

| Without drying system | 5.6kWh/Nm3 | ||

| Hydorgen output 450Nm3/h | With drying system | 5.1kWh/Nm3 | |

| Without drying system | 4.8kWh/Nm3 | ||

| Cooling | Cooling mode | enclosed loop | |

| Feed water | Partial consumption of electrolyzer | 75-450L/h | |

| Electrolyte | T mode | 30% wt KOH | |

| Operating conditions | environment | Indoor\outdoor | |

| Temperature range | ·-10℃to +35℃ | ||

.jpg)