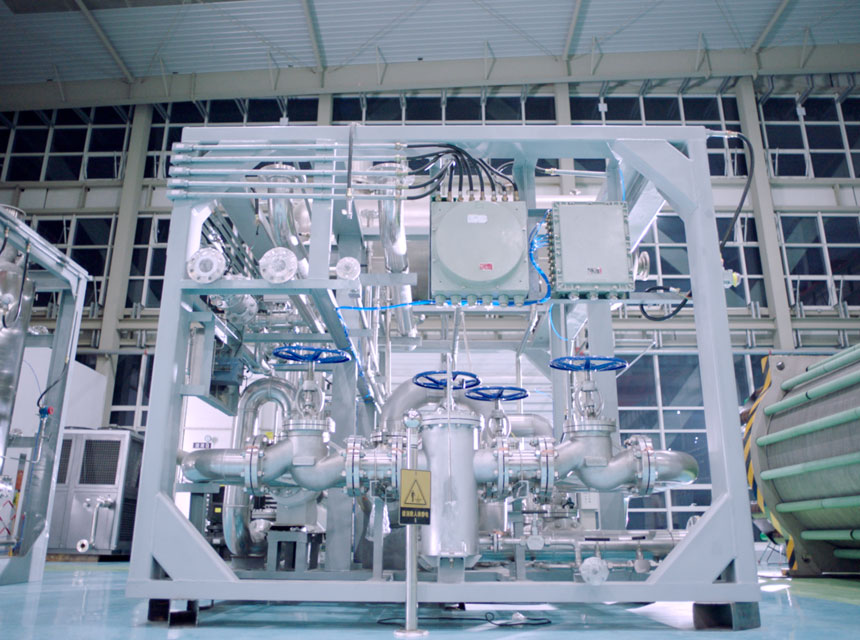

The electrolyzer includes module, skids (processing, drying and purification), cooling water system, PLC control cabinet, rectifier, gas analyzing instruments.

5MW / 10MW Alkaline Water Electrolysis

Advantages:

1. Low energy consumption

The voltage of the conventional electrolyzer is 2V, and the current density is 3000A/㎡, while the new electrolyzer HELA2000/HELA2000Plus can reach the current density of 4300A/㎡ under the voltage of 1.92V in the small chamber. Therefore, electricity consumption is reduced compared to conventional electrolyzers. The DC power consumption of the 2000Nm³/h Hygreen electrolyzer is less than 4.6kW h/Nm³H2, and the minimum of Plus is 4.2-4.4kW·h/Nm³H2, which is 2.13% lower than the DC power consumption of the conventional electrolyzer (4.7kW·h/Nm³H2), and the highest reduction is 6.38% or more.

2. Wide load

The new type of electrolyzer adopted has a maximum adjustable range of 110%. The new Hygreen electrolyzer has a current density of 4300A/㎡ under the voltage of 1.92V in the small chamber, and a current density of 6000 A/㎡ under the voltage of 2V in the small chamber. It is more adaptable to the high volatility of renewable energy and provides a more economical solution and possibility for a more reasonable allocation of hydrogen generation from photovoltaic wind power.

3. Boot speed

Improved the control method and shortened the start-up time.

The volume of the electrolytic cell is greatly reduced by increasing the current density, which is beneficial to the temperature rise and temperature control of the electrolytic cell. Greatly reduces electrolyzer full load state. PART 04 Advantages of HELA2000/HELA2000Plus

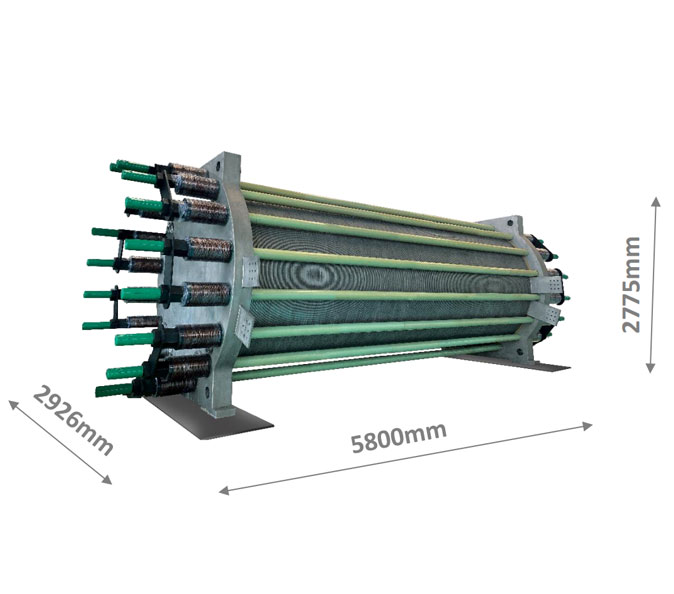

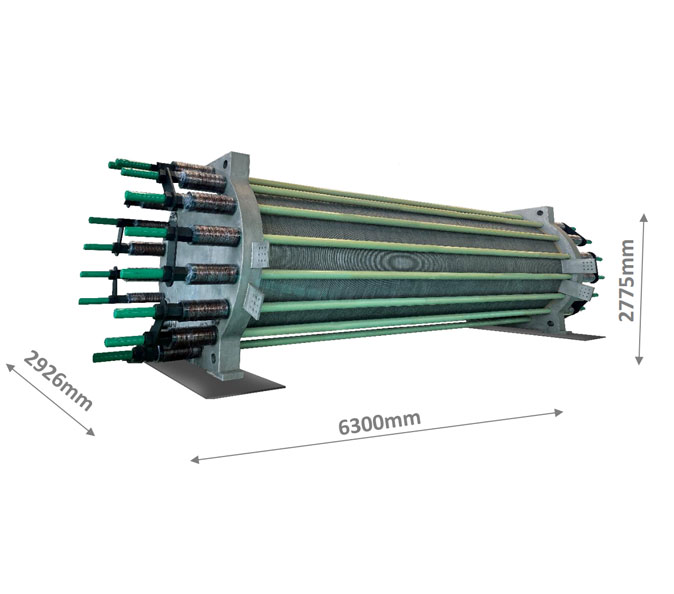

4. Small size and highly economical

The change of materials also greatly reduces the weight of the electrolyzer, which is reduced to about 70% of the weight of the original electrolyzer. Greatly reduces engineering problems during assembly, transportation, installation, commissioning, operation and maintenance. The cost of transportation, installation, commissioning, operation and after-sales maintenance is reduced. Low power consumption and wide load greatly reduce the operating costs of the project, improve the matching degree of power generation and hydrogen generation, and thus increase the return on investment of the overall green hydrogen project.

5. High performance

The new electrolyzer structure has greatly improved the purity problem in the traditional diaphragm, and improved the purity of the hydrogen/oxygen. The purity of oxygen before purification is increased to over 98.5%. The purity of the hydrogen produced by the electrolyzer is above 99.8.

6. Life Span,Stability and Safety

The electrolytic cell adopts a flat plate, which avoids the disadvantage of the diaphragm being damaged as the usage time increase in the conventional electrolytic cell, which was caused by the difference in the plate stamping nipple, thus ensuring the life span, stability and safety of the electrolytic cell.

Parameter

|

HELA1000 |

HELA2000 |

HELA2000 + |

|

|

Electrolysis Technology |

Alkaline |

Alkaline |

Alkaline |

|

Stack Power |

5MW |

10MW |

10MW |

|

System Efficiency |

78% |

74% |

78% |

|

Output Pressure |

1.6MPa |

1.6MPa |

1.6MPa |

|

Start-up Time |

20min |

15min |

15min |

|

<20min |

<15min |

<15min |

|

|

Water Consumption |

900L/h |

1,800L/h |

1,800L/h |

|

Stack Design Life |

80,000h |

80,000h |

80,000h |

|

Hydrogen Gas Production |

1,000Nm³/h |

2,000Nm³/h |

2,000Nm³/h |

|

Oxygen Gas Production |

500Nm³/h |

1,000Nm³/h |

1,000Nm³/h |

|

Current Density |

3,000A/㎡ |

4,500A/㎡ |

6,000A/㎡ |

|

Voltage of Single Cell |

1.84V |

1.96V |

1.84V |

|

DC Power Consumption |

4.4kWh/Nm³ H₂ |

4.7kWh/Nm³ H₂ |

4.4kWh/Nm³ H₂ |

|

Operating Range |

30%-110% |

30%-110% |

30%-110% |

|

Hydrogen Purity at Outlet |

>99.80% |

>99.80% |

>99.80% |

|

Oxygen Purity at Outlet |

>98.50% |

>98.50% |

>98.50% |

|

Operating Temperature |

90±5℃ |

90±5℃ |

80±5℃ |

.jpg)